June Security "Mega-Operation"! Did you participate in these eye-catching actions?

Jul 07,2025

June marks the 24th National Safety Production Month. Company-wide, everyone actively participated in a variety of themed activities, thoroughly implementing the concept of "everyone talks about safety, everyone knows how to respond to emergencies—finding safety hazards around us." This ensures that safety awareness truly becomes ingrained in our minds, hearts, and actions.

Safety Education and Training

The company specially invited safety experts to the production lines to provide employees with vivid safety awareness training. Experts explained safety knowledge and precautions in an easy-to-understand manner, combining them with actual production situations. Meanwhile, the Machining Department of the Mold Factory organized employees to watch the promotional film "Finding Safety Hazards Around Us" and conducted on-site hazard identification training, allowing everyone to more intuitively understand potential safety hazards around them.

↑ Experts conducting on-site safety awareness training

↑ Machining Department conducting on-site hazard identification training

The Pressing Department, which uses a lot of special equipment such as overhead cranes and forklifts, conducted special training on the safe operation of special equipment. By detailing equipment operating procedures, maintenance methods, and emergency response measures, the training further strengthened employees' safety awareness when using special equipment, making everyone more standardized and cautious in equipment operation.

↑ Pressing Department conducting special equipment safety operation training

↑ Welding Department conducting on-site hazard identification training

Safety Knowledge Quiz

The company launched an online safety knowledge competition throughout the company. Subsequently, the Mold Factory took over and conducted the knowledge competition, further implementing the activity in various departments and teams.

↑ Company-wide online safety knowledge competition

↑ Mold Factory online safety knowledge competition

The Machining Department of the Mold Factory creatively combined safety production knowledge with the game "You Guess I Act." They cleverly incorporated content such as the wearing of personal protective equipment, production hazards, and workplace accident scenarios into the game, allowing employees to learn and master safety knowledge in a relaxed and enjoyable atmosphere, truly achieving the goal of education through entertainment.

↑ Machining Department "You Guess I Act"

The Tool and Die Adjustment Department, combining the actual production needs, integrated special equipment operation standards and company safety management regulations with the "Safety Sides" activity. Through this interactive approach, employees gained a deeper understanding and memory of safety knowledge.

↑ Tool and Die Adjustment Department "Safety Sides"

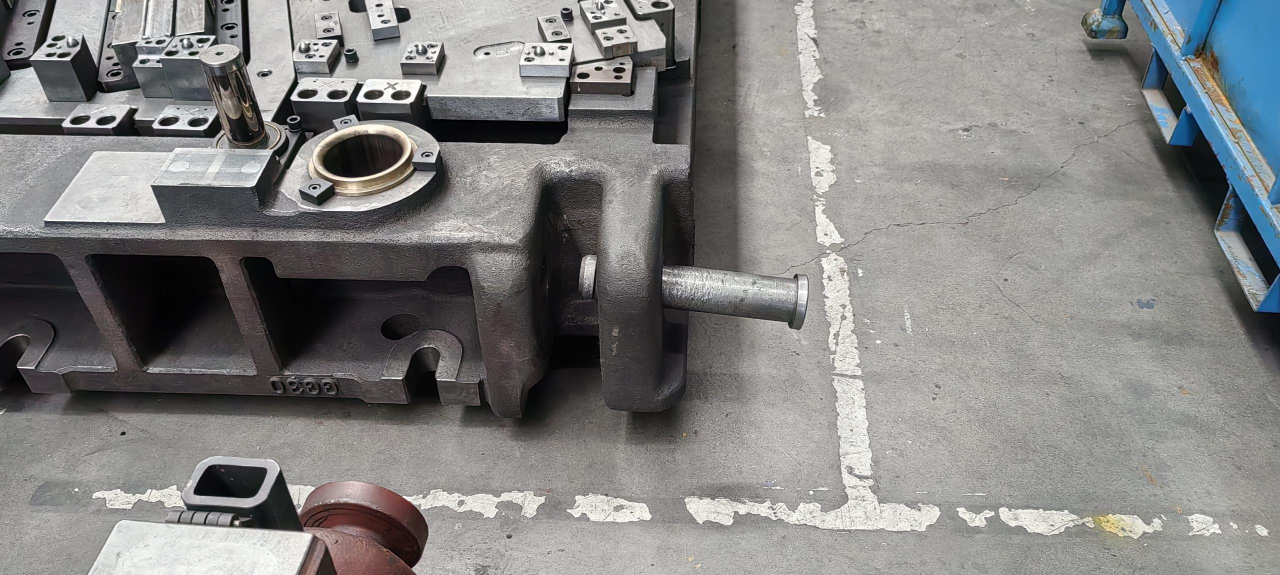

Hazard Identification

The company actively responded to the call to "find safety hazards around us" and launched a series of on-site safety hazard identification and rectification activities. Employees went deep into the production site, carefully checking every corner and every piece of equipment, leaving no stone unturned in identifying potential safety hazards. Departments and teams promptly rectified the identified problems, addressing each issue as it was found and eliminating safety hazards in their infancy, building a solid defense for the company's safe production.

↑ Molding rod exceeding the mold body

↑ Failure to wear safety helmets correctly

↑ Failure to clean the iron mud box in a timely manner

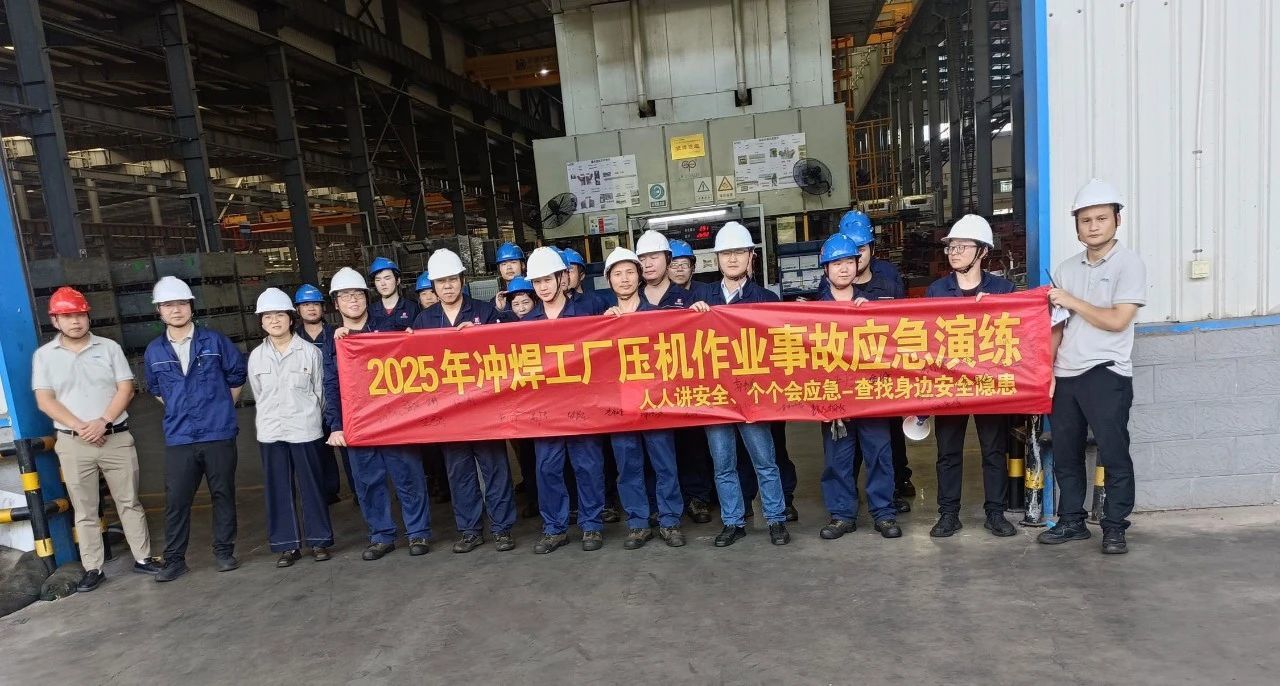

Safety Drills

"All talk and no action is worthless." To test employees' emergency response capabilities, the company held an "Emergency and Firefighting Practical Competition." At the competition site, participating teams competed fiercely, and judges carefully recorded the completion time and operational standards of each team. This competition not only tested the teamwork but also examined everyone's understanding and correct use of firefighting equipment, allowing employees to gain experience and improve their emergency response capabilities in practice.

↑ Competition site

The Tool and Die Adjustment Department, Machining Department, and Pressing Department conducted emergency drills based on their respective department characteristics. These targeted drills allowed employees in each department to familiarize themselves with emergency response procedures and improve their ability to respond to emergencies.

↑ Tool and Die Adjustment Department mechanical injury accident scene handling

↑ Machining Department mechanical injury emergency drill

↑ Pressing Department press operation accident emergency drill

Every roar of the production line relies on safety as a backup. Although the "Safety Production Month" activities have concluded, safe production has no end. Let's carry the safety "skill package" we've accumulated this month with us, adding more vigilance and standardization to our daily work, turning "everyone talks about safety, everyone knows how to respond to emergencies" from a slogan into a habit, and together safeguarding the safety of our production line!

Related News