Equipment

The company has a large number of high-precision production, R&D and testing equipment, mainly including large-scale high-precision CNC machining production lines, vertical machining centers, large-scale automated stamping production lines, hot forming press lines, intelligent flexible unmanned processing production lines, commissioning press lines, matching lines, five-axis laser cutting machines, three-coordinate measuring machines, portable 3D scanning and testing instruments, and welding robot production lines, etc.

CNC workshop

Debugging workshop

Debugging workshop

Xiaoji Jia Workshop

Intelligent flexible unmanned processing line

2600T hot die production line

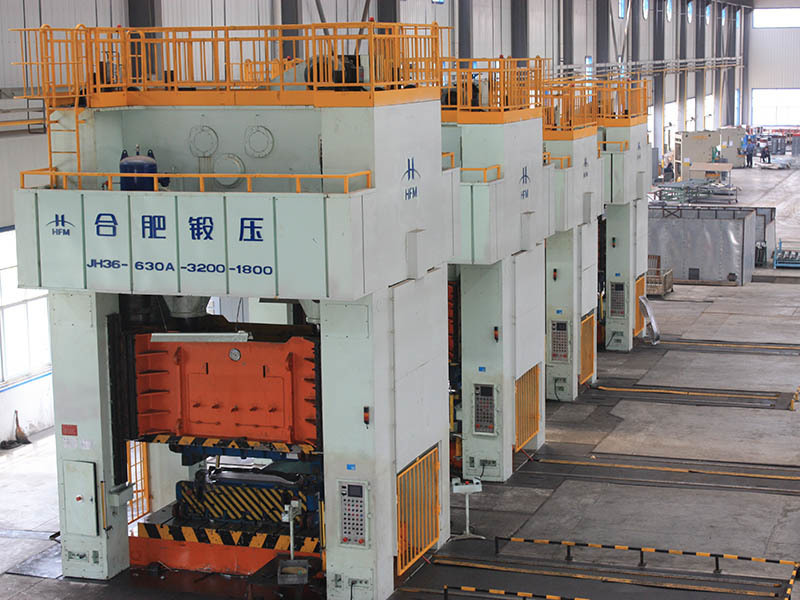

Press shop

Robot welding workshop

Robot welding workshop

2500T closed-loop multi-point multi-station continuous mechanical stamping production line